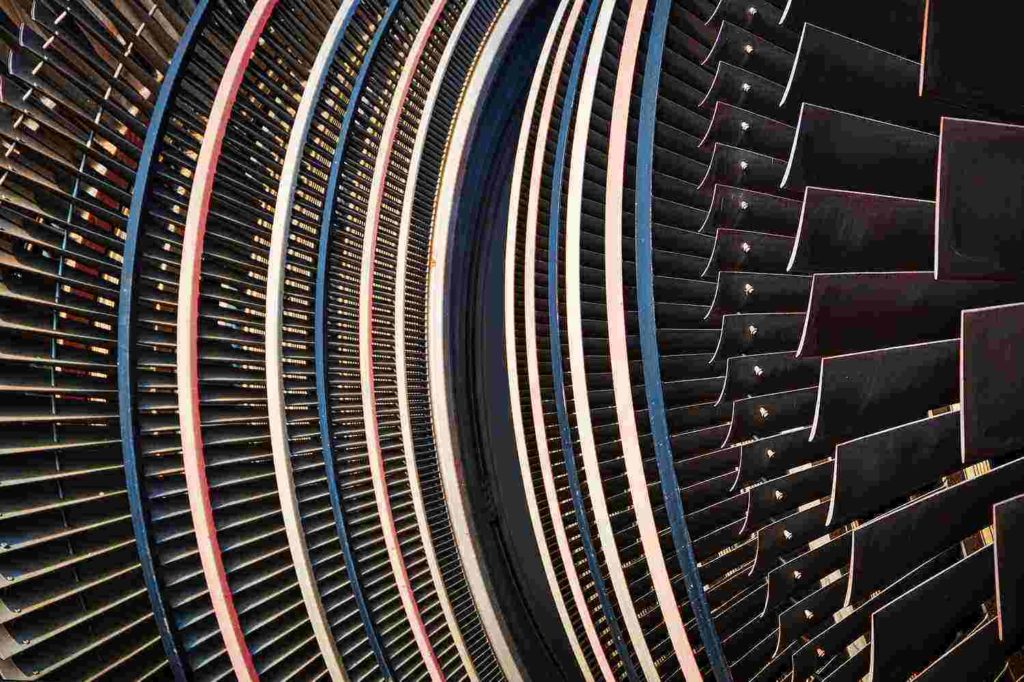

Varnish is an accumulation of oil oxidation and degradation compounds on machine components. It can cause a number of problems including restricting the flow of lubricants and clogging filters. Varnish is a frequent problem in high pressure and high temperature systems, and is usually caused by oxidation of lubricants, pressure-induced thermal degradation or dieseling.

As a lubricant oxidises and degrades, impurities are deposited on the surface of the equipment. Over time, they form a thick film-like deposit and if untreated can harden to a tough coating with the consistency of enamel. That restricts the flow of oil and moving parts and clogs filters, potentially leading to equipment damage and failure.

It can be difficult to detect varnish in a lubrication system without specialist oil condition monitoring. It is important to identify the root cause of the varnish formation which is usually air entrainment, electrostatic discharge or additive depletion. Where varnish is a concern, it is best to purchase oil based on the original equipment manufacturer’s (OEM) recommendations. Keeping the oil clean in your lubrication system can also greatly assist with varnish prevention and management. There are methods for removing varnish from a lubrication system including specialist filters and electric-charge filters, but in some cases a full system flush and chemical clean may be required which will be costly.

If you are experiencing problems with varnish, give our team a call and see how we can help.