SKF Lubrication Systems

Pure Lubrication is an official UK distributor for SKF, a global leader in the design and manufacture of advanced lubrication equipment.

Through this partnership, businesses across the UK gain access to world-class engineering combined with Pure’s hands-on technical support and installation expertise.

Together, SKF and Pure Lubrication deliver complete lubrication solutions that improve reliability, reduce downtime, and extend equipment life.

About SKF

For more than 100 years, SKF has been recognised worldwide for its precision engineering and reliable performance.

Known for its bearings, seals, mechatronics, and lubrication systems, SKF’s technology helps industries increase efficiency, safety, and machine life.

The company continues to lead the way in innovation, combining smart technology with practical solutions for global industries.

As a trusted partner, SKF supports manufacturers in steel, food production, automotive, and many other sectors — helping them run cleaner, safer, and more sustainable operations.

SKF Lubrication Equipment

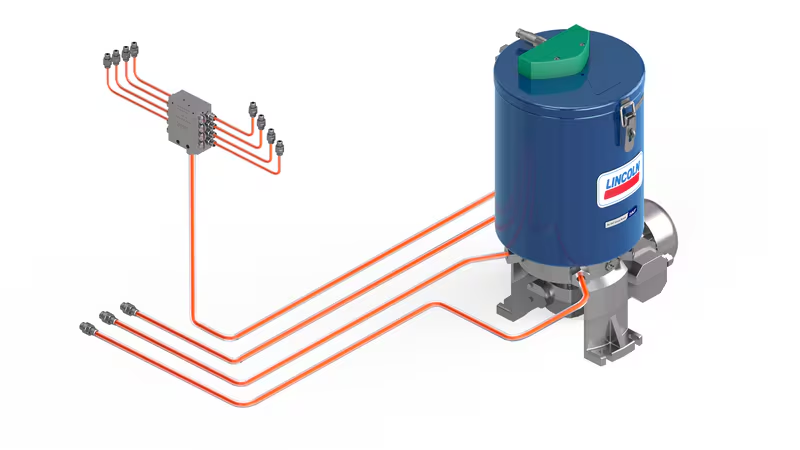

Lubrication plays a vital role in maintaining machine reliability. However, manual lubrication is time-consuming and often inconsistent.

An automatic lubrication system (ALS) provides a smarter, safer, and more cost-effective solution.

With SKF ALS technology, lubrication takes place automatically while the machine operates — eliminating the need for shutdowns.

Although the initial investment may be higher, the benefits are significant.

Labour costs fall, downtime is reduced, and equipment life is extended.

Consistent lubrication also helps prevent contamination and ensures every component receives the correct amount of grease or oil.

By removing the guesswork, operators can focus on production while SKF systems take care of maintenance precision.

See Our SKF Automatic Lubrication Systems

● Single-Line Systems: Ideal for applications with multiple lubrication points along a single line.

● Dual-Line Systems: Ideal for larger-scale application requiring reliable lubrication across long distances and multiple lubrication points, even in harsh conditions.

● Multi-Line Systems: Designed for applications where each lubrication point requires an independent supply of lubricant for precise and reliable operation.

● Automatic Smart Systems: Advanced lubrication solutions that use sensors and automated controls to monitor and adjust lubrication, optimising performance and reducing maintenance.

● Centralised Lubrication Systems: These systems deliver lubricant to multiple points in a machine or equipment from a central reservoir.

● Progressive Systems: Distribute lubricant to multiple points sequentially using a single pump.

● Metering Systems: Precisely control the amount of lubricant dispensed to each point.

● Oil Circulation Systems: Ideal for high-speed and high-temperature applications, ensuring continuous lubrication, cooling, and contamination removal.

● Oil and Air Lubrication Systems: Perfect for high-speed bearings and cutting applications, providing minimal but effective lubrication while preventing contamination.

● Minimal Quantity Lubrication Systems: Optimised for machining processes, delivering an exact amount of lubricant to reduce waste and enhance efficiency.

● Chain Lubrication Systems: Ensures consistent lubrication of chains, reducing wear, extending service life, and improving operational efficiency.

Benefits

- Significant savings in repair and spare costs

- Increased machine reliability

- Up to 50% savings in lubricant costs due to accurate timing and dosing of lubricants

- Fewer shutdowns and production losses

- Reduced environmental impact

- Greater workers’ safety

Why Choose Pure?

With over 200 years of combined industry experience, the Pure Lubrication team offers expert guidance from selection to installation.

We help you identify the best SKF system for your specific needs and provide complete aftercare, including repairs, spare parts, and servicing.

Our commitment ensures every client achieves maximum equipment uptime, reduced maintenance costs, and complete peace of mind.