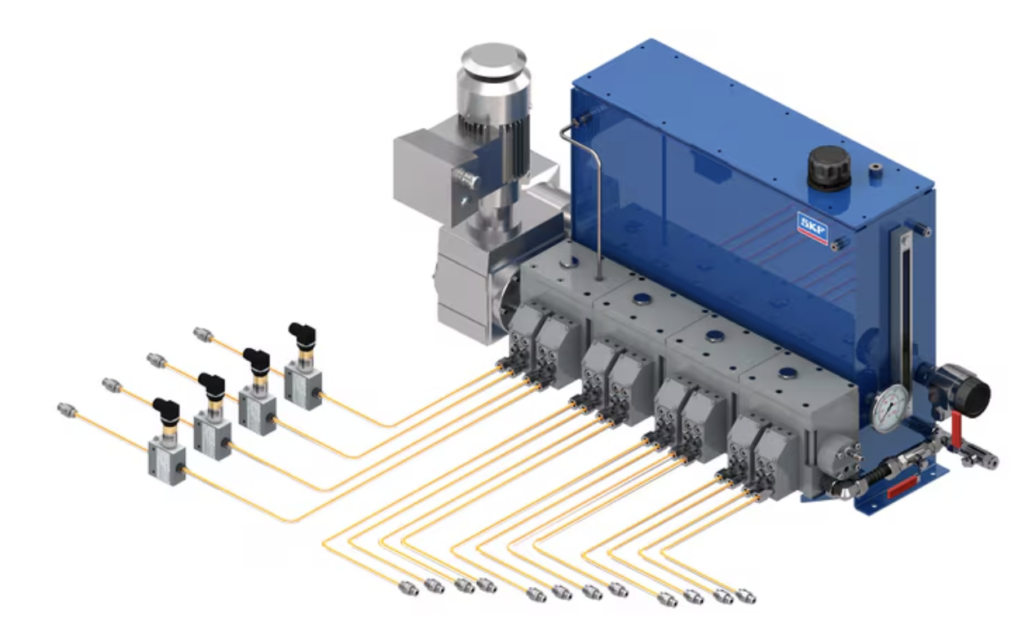

Multi-Line Lubrication Systems

SKF multi-line lubrication systems deliver precise amounts of lubricant to several lubrication points without extra metering devices. Each lubrication point has its own pumping element, ensuring accuracy and reliability. As a result, these systems maintain consistent performance, reduce wear, and extend the lifespan of critical machinery.

Benefits

Durability: Robust pump series built for continuous 24/7 operation.

Simplicity: Provides ongoing lubrication without electrical cycle timers in most setups.

Versatility: Allows selection of individual pump element characteristics and oil reservoir size.

Precision: Enables fine-tuned stroke volume adjustment at each pumping element.

Wide Range: Works across various lubricant viscosities thanks to special design and piston clearance.

Safety: ATEX explosion-proof versions available for hazardous environments.

Flexibility: Optional low-control valves or progressive metering devices can be added for extra efficiency.

Applications

These systems perform reliably in many demanding sectors. They are ideal for:

Vacuum pumps, compressors, and hyper-compressors

Combustion engines for valve and cylinder lubrication

Oil total-loss and small oil circulation systems

Rubber-mixing and plasticiser oil supply

Construction, mining, and tunnel-boring machinery

Forging, bending, and cutting presses

Crushers, cranes, conveyors, and pumps

Water, slurry, and heavy-duty operations

Because they meet ATEX and API standards, SKF systems suit industries where safety and precision are essential.

Multi-Line Oil Lubrication Systems

A multi-line oil lubrication system includes a pump unit, control devices, tubing, and fittings. Each lubrication point runs with a dedicated pumping element, creating a simple yet dependable setup.

These pumps operate mechanically, electrically, or hydraulically. Their replaceable pumping elements, usually driven by an eccentric cam, provide flexibility. Depending on drive speed, gearbox ratio, and element size, delivery ranges from 0 to 227 cm³/min (0 to 13.85 in³/min). Moreover, by changing piston diameters and stroke settings, users can adjust lubrication volume per outlet.

SKF multi-line oil pumps perform under pressure up to 4,000 bar (58,000 psi) and suit heavy-duty applications across most industries. Consequently, they are trusted where long-term reliability truly matters.

Multi-Line Grease Lubrication Systems

Multi-line grease pumps can also operate mechanically, electrically, or hydraulically. The interchangeable pumping elements use an eccentric cam for smooth motion. Depending on configuration, delivery ranges from 0 to 35 cm³/min (0 to 2.13 in³/min).

Each system includes a synchronised stirrer that mixes the grease and prevents hardening. This feature ensures a consistent flow and reduces maintenance interruptions. Typically, these systems handle lubricants up to NLGI 3.

In addition, each pump outlet can be customised by selecting elements with different piston diameters or stroke settings. With options ranging from one to thirty outlets, SKF’s pumps adapt easily to varied industrial needs. For example, models such as P 215 and P 230 are perfect for plasticiser oil delivery in the rubber sector.

Why Choose SKF Multi-Line Systems from Pure Lubrication

SKF’s multi-line systems combine precision, efficiency, and reliability to protect your assets. When you partner with Pure Lubrication, you gain access to SKF’s proven engineering and our expert support team.

In addition, our tailored lubrication solutions help reduce downtime and improve operational performance. Contact Pure Lubrication today to discover how SKF’s multi-line systems can keep your equipment running at its best.

Our Contact Details:

Glasgow Office

4.5 Kirkhill House Office Park

81 Broom Road East

Newton Mearns

Glasgow, G77 5LL

United Kingdom

Inverness Office

Suite 1, East Wing

Lyle House

Fairways Business Park

Inverness, IV2 6AA

United Kingdom

Tel: 0800 612 3536

Email: sales@purelubrication.co.uk