SKF

Single-line Lubrication Systems

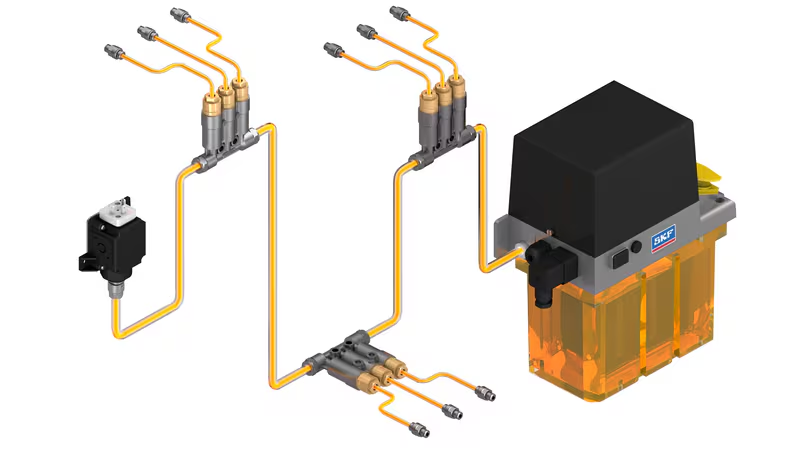

SKF single-line lubrication systems are designed for small-to-medium line lengths and are compatible with almost all lubricants. Operating on a simple yet effective principle, a central pump station automatically delivers lubricant through a single supply line to metering devices.

Each metering device serves a specific lubrication point and can be adjusted to release the exact amount of grease or oil required. The system is versatile, capable of servicing a single machine, distinct zones on one machine, or even multiple separate machines.

Benefits

Easy to understand, install and maintain

Suitable for nearly all types of lubricants

Reliable operation with minimal downtime

Simple to expand or adapt for growing systems

Continues to run even if one point becomes blocked

Capable of pumping long distances and performing across a wide temperature range

Improves worker safety through automated, consistent lubrication

These advantages make SKF single-line systems an ideal solution for industries seeking efficiency, safety, and precise control over lubrication.

Applications

SKF single-line systems are used across a wide range of industrial and manufacturing sectors, including:

Machine tools

Automation and robotics

Printing machines

On- and off-road vehicles

Construction and forestry machinery

Cement and materials handling

Food and beverage processing

Railway and transportation systems

Steel and heavy industry

Their flexibility and reliability make them suitable for both standard and demanding environments.

How Single-Line Metering Devices Work

All single-line metering devices operate almost in parallel, allowing for even distribution of lubricant. There are two main working principles, depending on system requirements.

Pre-lubrication metering devices:

In this type of system, the pump feeds lubricant through the main line into the metering device. Each discharge delivers a pre-stored amount of lubricant to the lubrication points, driven by the pump’s pressure.

Once the main line is relieved of pressure, the remaining lubricant shifts into the accumulator inside the device, ready for the next lubrication cycle. This process ensures consistent and repeatable delivery, keeping machinery running smoothly.

Re-lubrication metering devices:

During each lubrication cycle, lubricant flows into the accumulator chambers of the metering devices. The stored quantity is released only after the main line’s pressure has been relieved. This process – known as the re-lubrication effect – provides controlled, metered discharge to each lubrication point.

Quantities for both pre- and re-lubrication systems can be easily adjusted by changing the metering nipples, allowing for simple system tuning and maintenance.

Learn more about SKF’s single-line lubrication technology in the video below.

Our Contact Details:

Glasgow Office

4.5 Kirkhill House Office Park

81 Broom Road East

Newton Mearns

Glasgow, G77 5LL

United Kingdom

Inverness Office

Suite 1, East Wing

Lyle House

Fairways Business Park

Inverness, IV2 6AA

United Kingdom

Tel: 0800 612 3536

Email: sales@purelubrication.co.uk